So, you’re only interested in managers? What about everyone else?

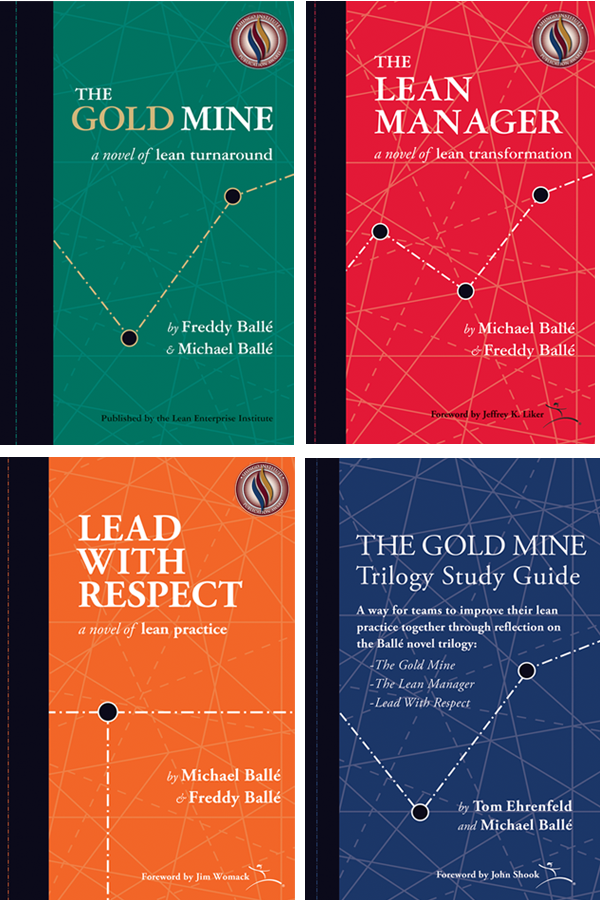

Have you considered most of your workforce who are individual contributors? I would bet that many of them are critical to your success. That includes your hourly workforce doing the actual value-added work. I mention this because a successful lean turnaround is not only all about people; it is all about all your people. You need everyone to buy in to become a lean enterprise.

Start by addressing people’s natural fear that comes with any significant change.

Let’s start by considering the hourly workforce. In my experience, you will get the least resistance here if you go about it correctly. Start by addressing people’s natural fear that comes with any significant change. Assure them that no one will lose their job due to kaizen, and, because few people will initially believe you, you will have to prove this claim over time. Next, get people involved in changes that affect their work. Those doing the work will always generate the best improvement ideas. Organize the company to catch and act on these ideas, staffing your kaizen teams equally with hourly employees and salaried ones.

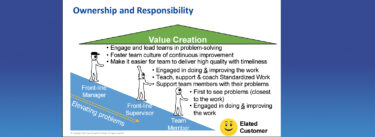

Giving people ownership of their improvement will help them immediately understand that, through kaizen, you are making their jobs easier and safer by acting on their ideas. Because it will take time for the kaizen-related changes (such as standardized work) to stick, you will need to rely on your shop floor management. Regardless, your hourly employees will understand the value of the lean changes faster than the rest of your team.

To motivate employees further, I strongly recommend a profit-sharing program sharing the inevitable gains.

To motivate employees further, I strongly recommend a profit-sharing program sharing the inevitable gains. Including all employees from the CEO on down will be a great motivator across the board. For example, at Wiremold, we created a profit-sharing pool that shared 15%of the pre-tax earnings with everyone.

Profit-sharing alone won’t get you buy-in from all your managers, especially those you need the most — the senior executive team that reports to the CEO. Do not expect miracles: these smart people achieved their positions by doing things the traditional way, so convincing them will take time. You will need to get all the executive team members to buy into lean and function as one aligned team. They will have to stop pointing fingers at each other when something goes wrong. So, for starters, stop being the referee for their squabbles; make it clear instead that you expect them to work any issues out among themselves.

Next, insist that every senior executive spends five to six weeks per year on full-time kaizen teams, which is the only way they will learn the power of lean as it shapes the entire company. They can only become lean experts by doing kaizen themselves. It will be a struggle, but you must force this to happen.

Convincing Middle Management

I have found that the biggest hurdle you will face is resistance from middle management, who are often very set in their ways. As a result, they will have to make pretty dramatic changes from how they have previously operated to foster the team atmosphere required by lean. They will push back against change, such as going from a functional organization run by a group of supervisors overseeing standalone operations to a value-stream structure run by team leaders with a much broader scope of responsibility. At Wiremold, we found that few of our former supervisors could transition to a team leader role. Their skills and knowledge were still valuable, but they delivered more as individual contributors than managers. Still, we changed their responsibilities without firing them.

Getting middle management to buy into lean happened the same way as everyone else: they learned by doing.

Getting middle management to buy into lean happened the same way as everyone else: they learned by doing. People from this group participated in multiple kaizen teams, often as team leaders. Some rotated into our kaizen promotion office full-time, where they accelerated their learning. Because we reviewed the progress of the team leaders weekly with the entire senior management team, we had a good feel for how they were progressing.

Bringing along the shop floor leaders under the team leaders was more challenging. Many were learning lean but treated our hourly associates poorly. We built our new lean culture on respect for people, but old habits die hard, and direct supervisors kept the “shut up and just do what I say” spirit alive. We tackled this by assessing the behavior of direct supervisors in an employee survey, and, after some frank discussions around problems that emerged, we would make necessary changes.

We helped the individual contributors, primarily our salaried workforce, get on board by giving everyone a chance to be on multiple kaizen teams. Because to succeed in adopting lean, you need everyone to constantly spiral upwards in their skills, knowledge, and effort. Therefore, management prioritized the responsibility of continually growing the workforce’s skills.

… management prioritized the responsibility of continually growing the workforce’s skills.

We did so in several critical ways. First, when hiring anyone — but especially engineers we decided that we would not hire anyone from a non-lean (batch) company as they would have to spend too much time “unlearning” the batch mentality. So we recruited young engineers directly out of school instead. Next, we asked both new hires and anyone that we were thinking of moving into a management position to take a simple personality test that weeded out potential management problems and indicated who could work in a team environment.

We also initiated an annual review of each department’s top and bottom ten percent of performers. The entire senior management team reviewed each one to ensure there was agreement. The top ten percent had to have a detailed plan for how we would advance them in the company. The bottom ten percent were made aware of their status and given an improvement plan with specific time frames. In almost every case, this under-performing group made substantial improvements and became solid performers. Usually, those who did not want to put in the effort decided independently to leave the company. As a result, we rarely had to fire anyone and rarely lost someone we wanted to keep.

The top performers did extensive kaizen work to build on their lean learning, and we got creative in trying to develop this next generation of management. For example, we put a manufacturing engineer in the kaizen office for a couple of years and then assigned him to learn the commercial end of the business as part of the sales force. We also made two regional sales managers who wanted to run a subsidiary company VPs of operations of a couple of our smaller companies so that they could build their hands-on lean knowledge.

Ultimately, the most influential factor in converting people who ‘didn’t buy in to lean’ was the unrelenting push from the top.

Ultimately, the most influential factor in converting people who “didn’t buy in to lean” was the unrelenting push from the top. When the CEO fully commits to lean and aggressively pushes the transformation through constant communication, training, and kaizen, the only choice is to get on board or leave the company. Of course, a few individuals may resist for a while. However, if everyone around them is fully committed—to participating on kaizen teams to learn how to see the waste and remove it—they will get on board before long or leave.Still, I know that sometimes you have to give people a chance to come around, and when you do, they usually react in one of two ways. In my experience, some of the most negative people at first wind up being your top lean zealots, and those who continue to resist will quit on their own.

Understanding Lean Transformation

Discover Why Your Lean Effort is Failing, and What to Do Differently.

Great knowledge shared. Thank you for the reliance and leadership example

Thanks Art. I am hoping you’ll speak to the incentives of the senior Management and C Suite, where Lean initiatives go to die when management changes. Wiremold and ThedaCare seem to be two examples of successes that couldn’t sustain when the CEOs left.

Thanks Art

Please keep sending the posts! I get my Workday motivated by reading them and then practicing to learn and improve on the daily basis

Thanks so much

William, thanks for your nice comments. I’m glad you enjoy the posts. All of us that live and practice lean learned from someone else that was willing to share. I’m just trying to pass on some of the things I have learned and I hope you will be generous in passing on your lean knowledge as well.