In Lean Thinking, by James P. Womack and Daniel T. Jones, the first two lean principles are about value. The first is to specify the value, and the second is to identify the value stream. Despite this focus on value, organizations that practice lean too often focus on eliminating waste and rarely focus on increasing value. Perhaps because waste is often easier to identify than value, it becomes the focus of their efforts.

The misplaced focus on eliminating waste concerns me for two reasons:

- It takes focus away from value.

- It often eliminates waste from an individual’s perspective rather than from the value stream perspective.

Increasing Value Compared to Reducing Waste

Don’t get me wrong. I’m not advocating that you should ignore and accept waste in your value streams. Instead, I contend that it would be better to emphasize increasing value over reducing waste. When most of us eliminate waste, we often assume that it increases the value-creating work, but that isn’t always the case. Value will only increase if you are intentional and deliberately focus on increasing value. What you want to achieve is having a higher percentage of the work being value-added compared to waste. Here are a few of the ways you can do this:

- Increasing Value

- Reducing Waste

- Increasing Value and Reducing Waste

In my opinion, two places offer considerable opportunities to increase value:

- Enabling people to create more value.

- Creating new value through the product and service development process:

– Learning through experimentation

– Understanding user/customer value

Increasing Value through Enabling People

When waste is searched for and eliminated outside of a value stream perspective, it is often in service of enabling people. Empowering people to get rid of the frustrations they perceive as waste is a great way to increase their engagement. Both removing people’s frustrations and authorizing people to remove their frustrations are part of a leader’s role in creating a system that enables people to create value while achieving their full potential.

However, this is not the same as eliminating waste from a value stream perspective, as described in Lean Thinking. When reducing waste, people need to understand the entire value stream to ensure that they aren’t generating more waste elsewhere. The last thing you want to do is play a game of waste “whack a mole.” You should not eliminate your waste and, in turn, create more work (waste) for someone else. Understanding value and waste together as a team through value stream mapping can ensure that you aren’t increasing waste for others by eliminating waste from only your perspective.

To enable people to create more value, you need to create the conditions for them to achieve their full potential. When people pursue their full potential, they enjoy their work more and perform better, leading to more value creation. You can do this by deliberately designing and using your systems, processes, and practices to enable people to have their needs for Purpose, Autonomy, and Mastery met.

Meeting Individual Needs Yields Better Performance

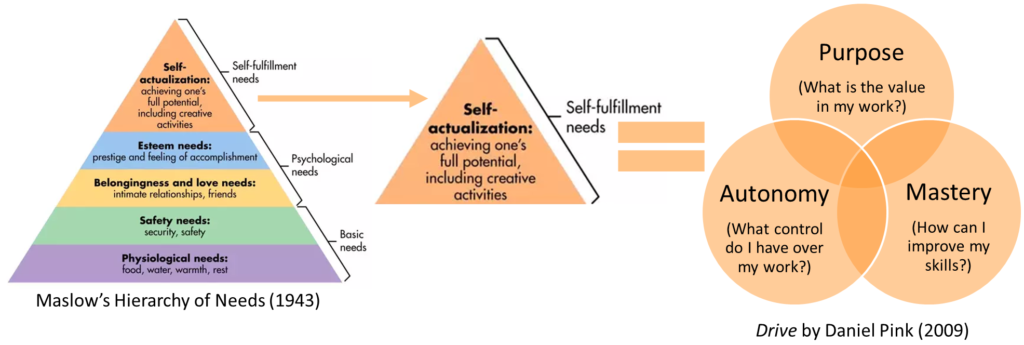

In the book Drive, Daniel Pink identified Purpose, Autonomy, and Mastery as the three things people require for better performance based on four decades of scientific research on human motivation.

- Purpose is understanding the value of your work.

- Autonomy is having some control over your work.

- Mastery is improving your skills.

The Purpose, Autonomy, and Mastery needs are at the top of Maslow’s hierarchy of needs as self-actualization. Usually, people need first to have their lower-level physiological, safety, belongingness and love, and esteem needs met before they can focus on pursuing their full potential and perform better—and creating more value.

As a leader, you need to be explicit about how you will support people in meeting their needs when experimenting with lean practices using PDCA / PDSA; this is how you show respect for people. Through creating the conditions to optimize learning and performance, you will spur more value creation while providing opportunities for people to grow and develop to reach their full potential; this is the essence of how value is created through lean thinking.

How will you enable people to create more value?

Increasing Value through Product and Service Development

While there is plenty of waste in product and service development that should be reduced, the potential benefits are more significant when you focus on increasing value. After all, the purpose of product and service development is to create new value.

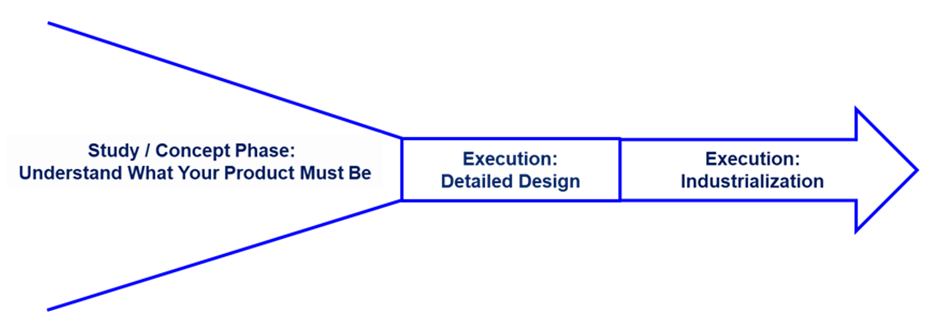

Phases of Product and Service Development: Study and Execution

Focusing on waste elimination can lead you to ignore the value of learning and understanding before executing. The study phase is very often short-changed in organizations because we tell ourselves that we must get started; we can’t waste time learning (creating new value); we have to execute the program. The resulting scope changes and corresponding rework, as we learn what the new product or service must be to create value, usually leads to significantly longer development times. It also requires more effort and leads to high levels of frustration for the team. Nobody likes making late changes that could have been prevented –or worse yet, not understanding what the product or service must be can lead to developing products and services that don’t provide customer value, making the entire product and service development effort a waste. Both are examples of people experiencing their work as waste, which is extremely disrespectful. People want to create and provide value.

How will you enable people to create and provide value through product and service development?

Increasing Value by Learning through Experimentation

Many people view any redundant activity as waste. However, many redundant product and service development activities are not waste — they are vital to new value creation. New value is created by learning through experimentation. Two widely used lean product and service development practices that add value, but are too frequently perceived as waste are the following:

- Repeating tasks in service of learning.

- Developing multiple design options in service of learning.

Running simulations and creating low-fidelity prototypes are tasks that enable rapid learning when done repeatedly throughout the development process. Developing multiple design options in parallel facilitates the learning needed to make the best design decision. These approaches allow learning early in the development process, when it is easier to incorporate it into the design to create more customer value without expensive late design changes.

When repeating tasks and developing multiple design options are perceived as waste, there is an assumption that you wouldn’t need to repeat the task or produce more than one design option if you picked right the first time. But few, if any, organizations can consistently guess the right design without the necessary learning to understand and create customer value. Gaining knowledge is a far more reliable way to ensure consistent high-performance product and service development than guessing. If you only look at the work with an “eye for waste,” you might wrongly eliminate repetitive tasks such as these. Further, having their work be perceived as waste is one reason people resist lean thinking in creative activities. Labeling someone’s learning work as waste is not only disrespectful, it also doesn’t create the conditions for them to create new value.

The irony is that lean is built on learning through iterative experimentation using PDCA / PDSA.

- Plan – What are you going to do? What do you expect to happen?

- Do – Run the experiment.

- Check or Study – What actually happened? How is it different from what you expected? What did you learn from what happened?

- Act or Adjust – What do you do with what you learned? What are you going to do next?

Learning through iterative experimentation is how knowledge and new value is created through lean practices. Capturing knowledge from experiments in a re-usable way, whether from repeating tasks or multiple design options, enables even greater value creation when used on future development projects. Not capturing learning as re-usable knowledge and not learning from repetitive tasks are indeed waste, as are some other redundant tasks – these wastes should be reduced or eliminated.

How will you enable people to learn in the service of creating new value?

Increasing Value through Understanding User / Customer Value

When you don’t take the time to learn and understand first, the resulting product or service is usually not as valuable as what you could have created. Just as you would spend time defining a problem before trying to solve it, you should understand user/customer value before executing product and service development projects. In the words of Einstein: “If I had an hour to solve a problem, I’d spend 55 minutes thinking about the problem and five minutes thinking about solutions.”

I’m not saying you should spend 90% of your time understanding and 10% executing, but that you should question if you are spending enough time understanding. Most organizations are not. Understanding value can start with observing for user/customer value:

- Ford and Toyota understand value through chief engineer immersion.

- Menlo Innovations understands value through high-tech anthropology.

- Ideo understands value through design thinking.

How will you enable people to observe for user/customer value?

Focusing on Increasing Value

Many organizations primarily focus their lean efforts on eliminating waste. While nobody wants waste in their value stream, it would be better to focus on increasing value. Emphasizing value creation reduces the risk that you will unintentionally remove value-creating activities while searching for waste. Emphasizing value creation also ensures that you deliver more value through intentionally focusing on creating new value.

How will you enable your organization to create more value?

What to do next:

The author is one of several coaches at LEI working to share lean thinking and practice with organizations and teams looking to enhance their product and process development success. To learn more about how they can help your organization, schedule a time to talk with a lean coach.