Dear Gemba Coach,

I’ve been practicing lean for many years and have learned to create one-piece-flow. However I still struggle with quality problems. I hear that quality comes first, but face many challenges trying to put this phrase into practice. What’s your take on this?

Safety always, quality first – these are the first values of lean on the gemba. You have a tough problem, one that I struggled with for years. I believe that you must take a new approach—that the key is to switch your mental model from “fix quality problems” to “fully understand quality causes.” Let us ignore quality systems for a second (I’ll come back to them), and think gemba.

The problem with understanding the causes of quality is that most processes are not easily visible. We know how to test the quality of the assembled product, but it’s often hard to test quality of the components or the assembly – and even harder in process industries. Imagine that you are making steel sheets, all rolled up. How can you tell whether there is a defect in the middle of a coil? Or if you’re assembling an appliance – how can you tell whether it’s going to work before you turn the switch on? This, then, is the starting point of lean’s approach to quality: let’s delve in.

First, you have to commit to be able to tell the difference between a good product and a bad product. And I don’t mean the paperwork, but the actual object in your hands. This is definitely a case of Ohno’s “look with your feet and think with your hands.” If you’re serious, you’ll find this an endlessly intriguing problem because of boundary conditions – obviously good versus clearly bad is easy to spot.

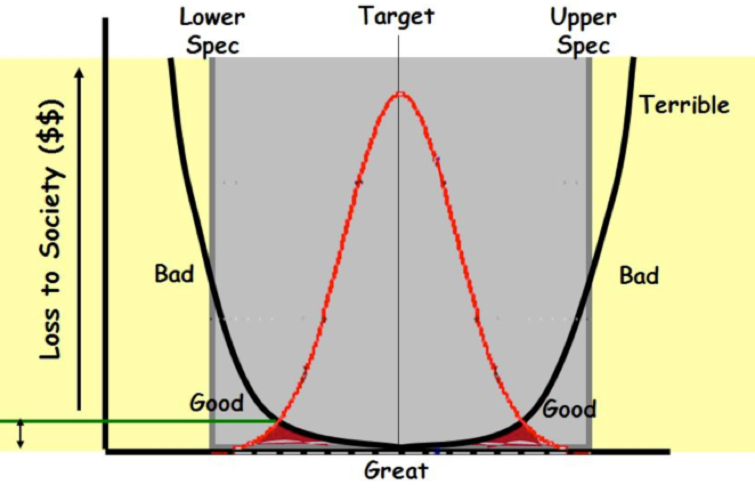

But many products are somewhere in between, and that’s when the real quality thinking comes in – what is the customer’s sensitivity range. Customer’s senses don’t usually work linearly. Recently I was looking at door frames on a construction site. The supplier doesn’t control the folding process visibly and when we looked at the inside corner of the frame, some showed significant gaps. But typically, a doorframe is not something you’ll notice much as you pass through. Nonetheless, there were thresholds: the misalignments I could see right away (having dealt with such issues often in the past on different products) and the misalignment the constructions guys could suddenly see because, well, how could you not see it. The customer might not consciously see that, but it will certainly impact their feeling about the quality of the apartment. So it’s really important to commit oneself to really understand the Taguchi utility curves of various aspects of the product. I’ve never seen one actually quantified, but just exploring the concept makes you look at products differently.

Once you’ve got a better feel for good versus bad product, jump in immediately. Don’t take “can’t do that” for an answer. Start working on how you could optimize OK or Not-OK results in the manufacturing process itself. Don’t do this on your own but start working with the operators and try to see through their eyes.

Word of Caution

I was in an equipment factory recently and we were trying to figure out how to avoid assembling defective, painted cast iron parts. How can the operator possibly tell whether there is rust under the paint somewhere (which is likely to crack later on and create blemishes on the product)? Of course they can’t, but when we asked the operators to isolate any cast part that simply didn’t feel right, we discovered that they picked up a lot of faults (some of them rust) in ways we couldn’t figure yet.

I’m not saying this is easy. I’m saying that the answer to your question is first to commit to know all there is to know about the boundary conditions between a good and not-good product and then get to work with operators to see how we can make better, smarter guesses at each step of the manufacturing process without being over selective.

Word of caution – the quality system is not likely to help you there, because the quality guys are likely to go crazy about this and, since they’re being challenged, impose hyper restrictive process rules (Design Of Experiments? Anyone?). That is clearly not lean – it just burdens the process with unnecessary costs and without learning anything about the process itself. Squeezing the supplier is rarely – if ever- an answer. We need to fully understand the problem, not make it go away through paperwork and restrictions.

The good news is that one-piece-flow helps significantly. As long as the operator can simply discard the dodgy part and help himself or herself from a full bin of the same component, that’s exactly what they’ll do – they just want to get on and make parts. With single piece flow (and I’m talking single-piece-flow, not two or three-piece flow), the operator has to deal with the suspicious part and either take the chance to assemble it anyways, or chose to call for help. Usually, guys want to do a good job, so if management asks them to shout out at any dubious component, they will. But management needs to want it.

Can’t Manage Quality

In the same equipment plant, we were walking our way back in the process and found ourselves at the inwards reception dock. The company had just made a huge leap towards better JIT by creating milk runs for their cast parts. Castings now arrived every day, not in twice a month shipments. So, the management team was standing there on the gemba around a stack of crates (the day’s arrivals) discussing the merit of milk runs until the sensei asked, “Well, are we going to open them or not?”

When they finally did (not without the usual grumbling and defensiveness about quality assurance and so on), as chance would have it, the very first part out of the box has a massive rust spot on it. The second had a small tear in it – I’m not making this up, I swear! The point is that leaning the process towards better JIT and eventually single-piece-flow is the best way to start looking at components part by part and stop thinking batches. This is the uniquely lean way to do quality.

Most quality systems are not set up to deal with that level of involvement in quality. Or when they are they become incredibly burdensome. The issue here is that many quality systems are designed to manage quality, not to develop quality maniacs. You can’t manage quality. You’ve got to immerse yourself in the theory of practice of the process. If we’re dealing with cast parts, we’ve got to start thinking in terms of materials variation, temperature controls, and design specs. No amount of paperwork is going to help with in-depth knowledge.

If I had to sum up lean’s unique approach to quality it would be TQC without the paperwork. Don’t work at batch level, focus at product level and start seeing that no problem, no matter how small, is uninteresting because we’re not trying to “fix” the quality issue, we’re trying to better understand how quality is built into the product by the process (or not). Quality and just-in-time work hand in hand. It’s a matter of attitude: go to the shop floor and work with operators to try to figure out how to visualize bad parts from good parts, bad process operations from good ones, and learn. As you do, quality will improve, teamwork will improve, and, ultimately, if you can report back what you learn to design engineers, products will improve as well.