Many people struggle with the use of visual tools as part of their daily management systems. One helpful way to frame this is to contrast the use of visual management at the gemba with the broader use of “obeyas,” which can be seen as thinking spaces for more than doing spaces.

One of the greatest wastes in management occurs when leaders do the job of their direct reports. Not only does that take any initiative away from subordinates by acting like they are dumb compliance machines, but it also means that the executives are neither focusing at their level nor doing their leadership job. It’s also a bellwether of poor management: the first panic reaction whenever a crisis hits in any organization is that everyone starts micromanaging the people under them, rather than do their own jobs.

So let’s start from the gemba, and build the system back up, shall we? Lean practice is built on providing operators with everything they need right at the value-adding place (the gemba) to produce good parts. Their team needs the right number of trained people, a stable volume and a clear indicator of progress; they require a deep understanding of OK versus not-OK at each station, and they must have components that they need not check before assembling them, and machines that work as they are supposed to. Operators should feel that they own and control their work environment and have a clear way to deal with unusual situations, as well as having confidence that their efforts are recognized.

Visual management supports these key lean principles with physical artifacts that help orient operators are such indicators as:

- Kanban cards providing autonomy on what needs to be done next

- A shop stock to own one’s production until needed by the internal customer

- An andon cord or button to call for support when something is off

- Visual identification of containers and machines to make sure all is in the best order to support standardized work.

- Visual standards to distinguish OK versus Not-OK

- A board to see whether they’re ahead or late on the schedule and note problems.

The picture below illustrates many of these items:

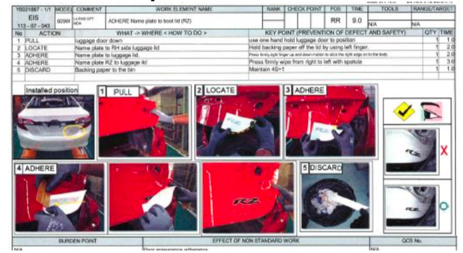

For instance, in this picture below (Courtesy of Toyota Australia) we can see visual management providing clarity about whether things are OK or not-OK at first glance:

Here we see clear work instructions:

Note that visual management is not there to control team members’ behavior but to guide their eyes: eye movement, hand movement, feet movement – to make it easy to get the job done right first time. The whole point of the visual management system is to support team members in their work, at takt time, and to make it easy for them to spot abnormalities and pull the andon chord.

It’s key to see this as part of a healthy daily management system. Obviously, keeping a work environment in top conditions so that team members can do a top job easily demands attention. Every day friction will occur. Small things get out of line and have large consequences (the grain of sand in the cog that stops the machine). Every day we discover some things that we didn’t know that change how we think about what we’re currently doing.

The basic thinking of lean is that we make daily efforts to eliminate muda, and to generate and encourage suggestions from team members to continuously improve safety, quality, flexibility and cost management. Ultimately the goal is to feed back this information to product and process development. To be able to visualize muda, we need a comparison base: this is what our standards are, i.e. the best-known combination of people and machines to deliver good products at takt.

Frontline management’s main job, therefore, is to create an atmosphere of respect of work standards, and standardized work, at all times, by all people. People will naturally need to be convinced of the validity of the standards first; and the best way to do this is to have worked at the improvement of the standard through kaizen.

The system needs a simple way to ensure that things are constantly cared for and kept in check. Visual management should be updated. Standards for Manpower, Machine, Materials, Methods should be respected (and when not, problems can be addressed). 5S can practiced by the teams. All of these frames for seeing muda are well established.

In other words, the daily management system is essentially about visualizing problems and making sure we get around to solving them. The elements of this system include:

- Key indicators (starting with safety and quality), and most importantly making sure dangerous situations and defects are counted at every step of the process – here’s one from a Toyota plant in China:

- A checking routine for frontline management, by which you ensure managers go to physical control points regularly.

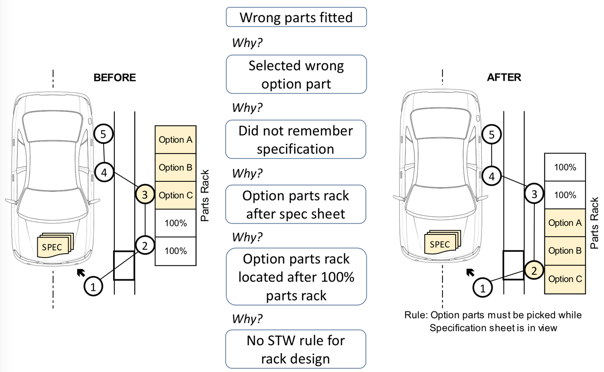

- Analysis and countermeasure plans of problems identified.

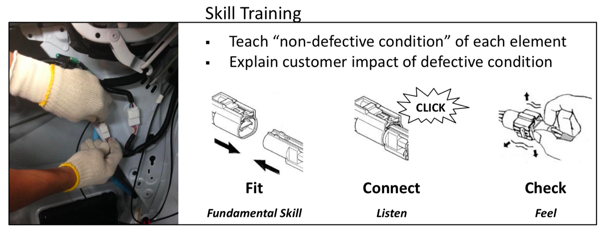

- Competency matrix to see where we are in terms of people leadership in each cell and skills training:

- Kaizen efforts so that teams own their own work and commit to routine improvement:

- Suggestion follow up system to make sure creative ideas are encouraged and supported.

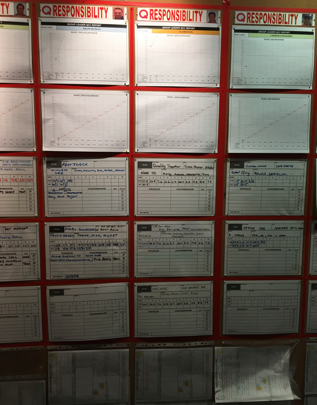

This daily management system will typically appear as a wall full of indicators and countermeasure plans:

The “Obeya” in Toyota tackles a different managerial challenge. As the story goes, the Chief Engineer of the Prius was challenged to come up with a car that would run double the distance on the same fill-up YET have the same spaciousness as a normal one. He investigated a large range of technologies, talking to all sorts of experts and the amount of information got out of hand, so he created one big room where all these various technologies would be exposed for people to understand what each person was doing and where they were going with this.

Obeyas are not about control, but rather, about facing challenges, discussing the hard problems and sharing how they interface with each other in the complete system that is a company, or a plant. For instance in this Obeya wall, courtesy of Boshoku in Brazil, managers explain how they’re working on various systems to improve how the plant works as a whole:

In this obeya, each function has a board to explain what they’re working from purchasing to production engineering and product changes for the local market:

These obeyas are really about solving a huge challenge in any organizational structures: creating better interfaces so that we all understand what each other is doing and how this fits together in order to have a business-level result.

The purpose of obeyas is very different from that of daily management systems. Very early on, Eiji Toyoda realized that one cause of Big Company Disease was functional specialization and rivalry and created countermeasures, starting with the Total Quality Management system in order to pierce the silos (in fact, this is also what a pull system with kanbans does in production). Obeyas are a thinking space, not a to-do list follow-through space:

- Are we facing solving the right problems?

- Do we all understand the situation the same way?

- Do we understand what each of us is trying to do?

- How can we help each other to achieve overall performance improvement?

One thing you might want to check with your obeyas is whether you’re not making the most common mistake I see in companies deploying lean: using a version of daily management system at executive level. Rather than help performance, this actually reinforces management’s tendency to keep their heads down and force action, putting pressure on their subordinates and often doing the job of the guy under them. And, as we discussed, this is the worst waste you can create.

Tools are tools – if all you know is a hammer you’ll see everything as a nail. The origin of tools and their purpose matters. Visual management is about guiding team members’ attention in doing their daily jobs well. Daily management systems are about helping frontline managers solve production conditions problems week after week by following indicators and following through with countermeasure plans. But “obeyas” are about fostering a greater cooperation between department heads so that they understand and face challenges better and solve customer problems at interfaces in the system in order to, every day, create more enabling systems for employees to add value.

Obeyas work best when seen as thinking spaces far more than doing spaces. They are a space for free exchange of knowledge, opinions and ideas so that we face the pain of real learning together and find the motivation of real progress as well.

Great article, Michael!

Can you elaborate on why it is bad for leadership to run a version of daily management? If the leaders do not have a place to view the status of Hoshin together with a glass wall how do they avoid doing the jobs of their subordinates and micro-managing? Curious on management and leadership standard work alignment.