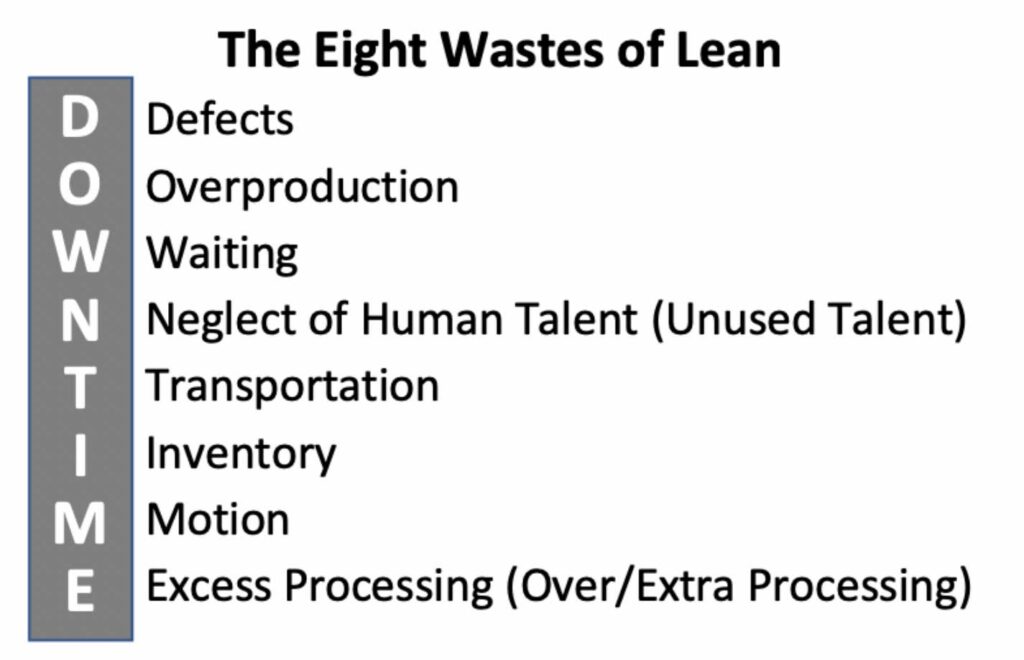

Originally there were seven wastes identified by Taiichi Ohno for the Toyota Production System. As lean evolved into the rest of the enterprise and around the world, an eighth waste, non-utilized talent, was identified. I and others use an acronym, “DOWNTIME”, to help remember the wastes.

The other day, I heard someone talking about Overproduction who mistakenly called it “Over processing” which is a name for a very different waste. It’s an easy error to make, and it really got me thinking about the important differences in the two, and how to recognize them in production processes as well as all processes throughout your business.

Overproduction is when more of a product, a service, or information is created than is needed at the time. A classic lean example from manufacturing is making a widget based on the production capability of a piece of equipment rather than the demand from a customer. An example from the office area is making more information packets for a course than there are students. In both cases even when the extra items might be used later, it then adds to other wastes like extra inventory, storage space, motion, tracking, and if the items end up never being used, material waste, and on and on.

Over processing is when physical or mental work is performed that does not have a customer or purpose and does not add value. An example might be a feature on a product that customers do not use. If you think about this single example, you probably can identify work waste that many individuals/departments would perform needlessly over the course of the lifecycle of the product. Another example might be collecting and distributing metrics or data that are not used for any action by anyone. A third example is when the precision level of the output is more than what is needed to increase clarity or value such as a really fancy PowerPoint graphic when a simple graphic or text provides equally clear information or calculating to the penny when only an estimate is needed.

Being able to see these wastes is always the first step. This is best done by going to gemba and talking with customers and employees.

Overproduction in the factory has historically gotten much more attention because when using tools of pull and flow based on customer demand, inventory reduces, and the value gained is usually concrete and pretty obvious. In many other processes and functions within a company, overproduction is easy to control and see as well (if anyone is looking for it). And, overproduction is often a huge waste reduction opportunity just waiting to happen. Identifying the waste and understanding the true demand is the starting point and then adapting the process to this demand at all points is the solution. This can be difficult for sure in some work environments, but will result in effective and great, high value outcomes as documented in so many lean examples.

Over processing on the other hand is very insidious. It increases without intent over time, is often hidden, and once in place is often not eliminated for years. We all do it at work unknowingly in small and occasionally large ways. You need to be able to see it! Over processing is subjective and requires much more concise input about the value or purpose of the work to identify it. And, you can only get that from your internal and external customers. “What is this service or product for? How do you use this?” Then, when you and everyone else involved in a process have an understanding of the value or purpose, you can start to see the current work that is not needed. This is precisely what kaizen improvement events are all about. Once the process is optimized, creating standards with periodic reviews to communicate to all is essential to avoid future over processing creeping in.

For products and services, look to the guidance provided in Designing the Future, the application of lean thinking to product development and process design. There are many LEI resources here to pull from for knowledge about these wastes: workshops, summits, Lean Posts, etc.)

Specifically for your internal office processes, you will find a crazy number of waste reduction opportunities—if anyone is looking! There are certainly some large ones, but there are countless small opportunities that dramatically add up especially when they are done over and over for a long time. For instance, maybe a very diligent worker likes to sort their work into three groupings, then put a check mark and initial on each one, review the batch, and finally send it for approval. At what point does this add to the value provided? It might, but it might not. Who decides? Who limits the time needed? These can be extremely difficult decisions to make individually and especially if the process has been done the same way for many years with no complaints. No complaints in no way means that waste does not exist in a process. The tools to address this challenge and make visible this type of waste exist in the lean tool kit. These include process mapping, gemba, upstream/downstream process collaboration, kaizen, job sharing, etc.

All the wastes are important to understand and know how to apply so that you can train your eyes to see opportunity even if we do not yet know how to improve the situation. The biggest risk is just assuming that how work is done today is the only way. Looking at your current state with “waste eyes” will help you see a better way and create a vision for continuous improvement large and small going forward.

“Overprocessing” usually comes from people who use the the “TIMWOOD” acronym. So it isn’t “wrong”, just a different work for “Extra Processing”.