If you or your team think the A3 process is only a problem-solving tool, think again.

“There is a lot more to the A3 management process and tool than we recognize,” says David Verble, who spent 14 years working for Toyota in North America, where he learned the A3 process and the plan-do-check-adjust processes from Japanese leaders in Japan and the U.S.

“There’s the problem-solving process but it’s also a process for change leadership, organizational and individual learning, and ultimately its purpose is to develop sustainable performance improvement.”

You’ll learn:

- Why A3s are not primarily problem-solving tools.

- How the A3 process builds sustainable performance capability.

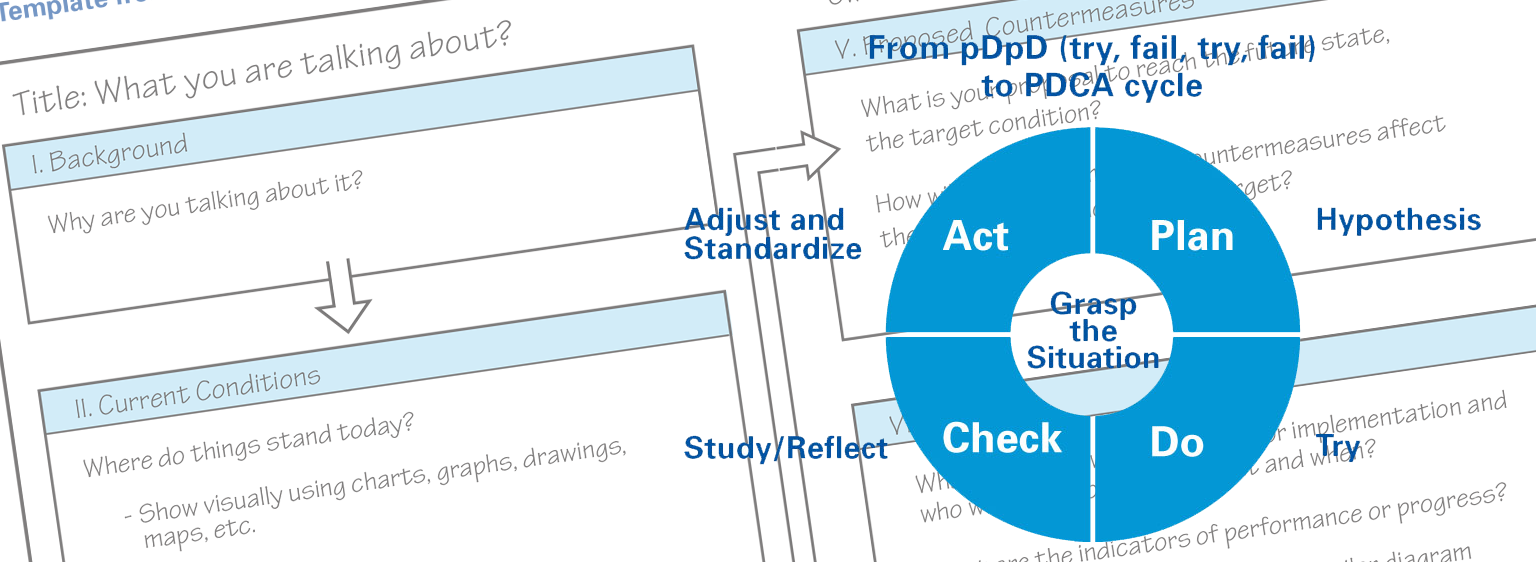

- Why you must start the PDCA problem-solving process with “check-adjust” steps before “plan.”

- Why the gemba (Japanese for where value is created) is not just a place but includes people too.

- Toyota managers sometimes say, “No standard; no problem.” But no standard is really a huge problem.

- How the A3 process develops capability through coaching, builds alignment within your organization, and guides continuous improvement.

thanks a lot for a value A3 seminar